Role: Lead Designer, Student Researcher

Duration: 12 months

Skills: Project Management, Digital Fabrication, Independent Research, Collaboration, Curation

Presented at the Following Conferences: Undergraduate Research, Scholarship, and Creative Activities (URSCA) @ UC Davis - June 2023

Western Regional Honors Conference (WHRC) @ University of Montana - March 2023

Environmental Design Research Association (EDRA) @ Mexico City - June 2023

PROJECT SUMMARY:

The pinnacle of my studies at UC Davis, this year-long project ties together knowledge from a wide range of disciplines, including industrial design, graphic design, biology, and research. Throughout my research process, I presented my progress and findings at several national conferences, and was awarded highest honors upon graduation for completing the project.

Visit the Eco Materials Website here: https://ecomaterialslibrary.com/

Emma Smith interacting with a sample from the Eco Materials Library wall

ABSTRACT

The Eco Materials Library at the UC Davis Department of Design Makerspace is a project created to increase student awareness around sustainable materials they can bio-fabricate themselves or source for their design work. The project has taken a close examination of bio-based materials with easy to source ingredients with a survey of existing material libraries and related publications. Material libraries are used by the design and architecture industry but very few universities have libraries available for student use and experimentation. In 2018, the United States produced approximately 35.7 million tons of plastic, 27 million tons of which ended up being sent to landfills (“Plastics: Material-Specific Data”, 2022). Plastic and the design industry have been inextricable since the 1950s. Today, designers and material scientists play a key role in the transition to healthy materials and reduce the damage caused by single-use plastics and planned obsolescence. According to the Environmental Protection Agency, “Bio-based materials refer to products that mainly consist of a substance (or substances) derived from living matter (biomass) and either occur naturally or are synthesized” and have the potential to replace plastics in product design and minimize environmental degradation (Curran, 2010). Reducing reliance on plastic begins with increasing awareness and education as well as providing better alternatives. The Eco Material Library has a new full wall display made from CNC cut plywood with a grid system of moveable dowels and shelves for students to feature new materials and prototypes. The project has a custom label system that features categories such as fugal, animal-based, mineral, microbial, plant-based, and recycled materials. The labels have icons that inform students if the material can be composited, locally sourced, laser cut, or recycled. The project is constantly evolving with student sample contributions and new future materials from global research.

Instructional signage to aid users when interacting with the Eco Materials Library wall

Detail shot of samples in the Animal-Based category

Eco Materials Wall installed in the Cruess Hall Makerspace

STEPS IN MY THESIS PROCESS (SIMPLIFIED):

1. Written Proposal

2. Research (Material Library Case Studies & Biomaterial Research)

3. Sketching & Prototyping (for entire library and for sample labels)

4. Sourcing Material Samples

5. Refining Designs & Implementation

6. Written thesis

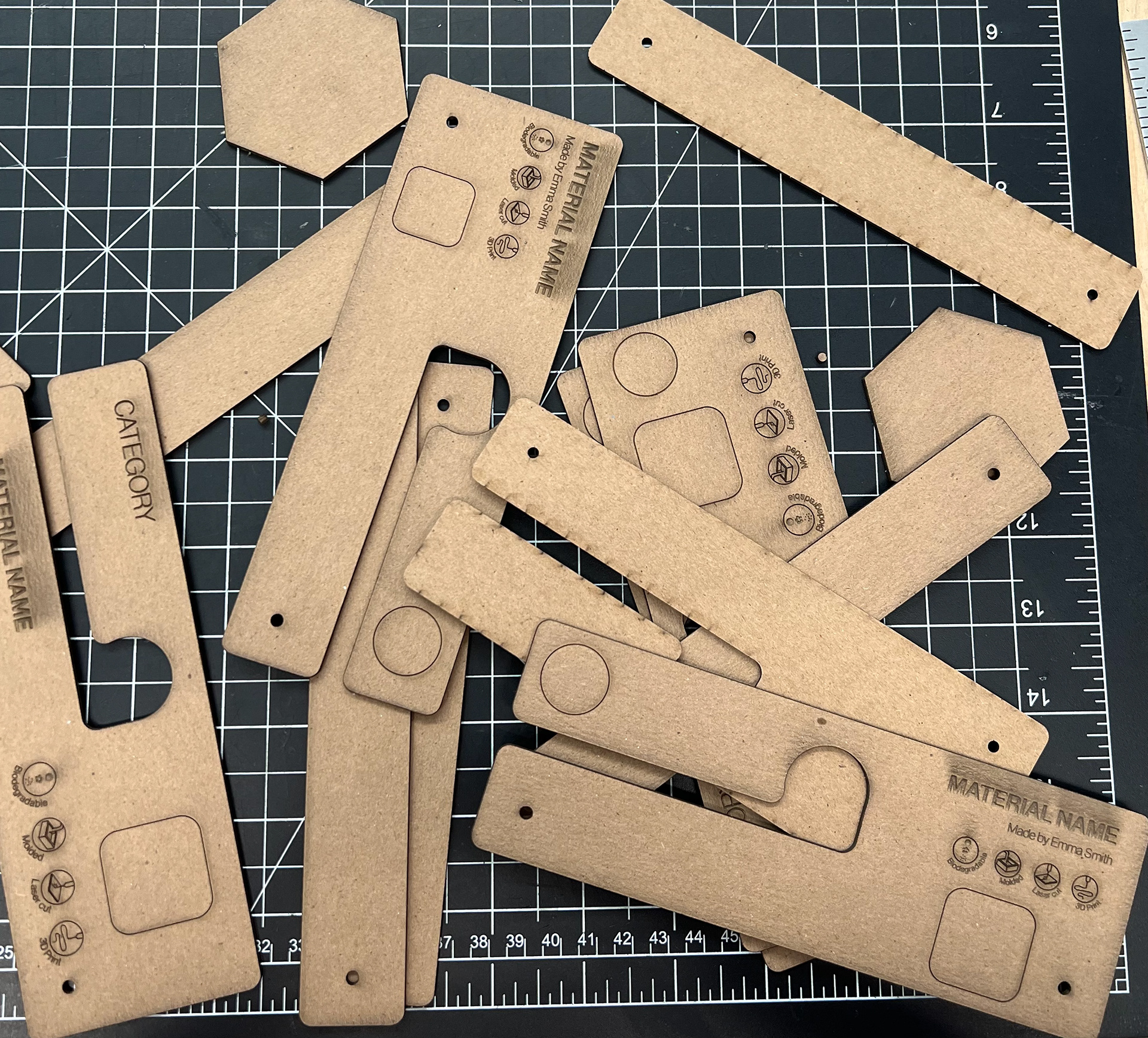

PROTOTYPING PROCESS: Designing Sample Labels

After completing several case studies on material libraries, as well as working with carpenter and MFA Design student Justin Marsh, I decided to design a label tag for each sample. The intention behind designing these tags is so that the samples can hang in various ways on a wall, as well as provide the user with basic knowledge of the materials, such as their main ingredients, potential uses, and its lifecycle. I went through many iterations in order to come up with the most effective design. I tested the first round of labels on a focus group in order to determine which combination of infomation in various locations around the label was the most effective. When I selected a design that I was happy with, I created a template for the labels using Adobe Illustrator, which can be used in tandem with laser cutting machines to automate the production process. Creating a template also allows the project to be able to grow after I graduate, so students and staff can add more samples into the library and continue to produce labels.

Final label design

Final label design

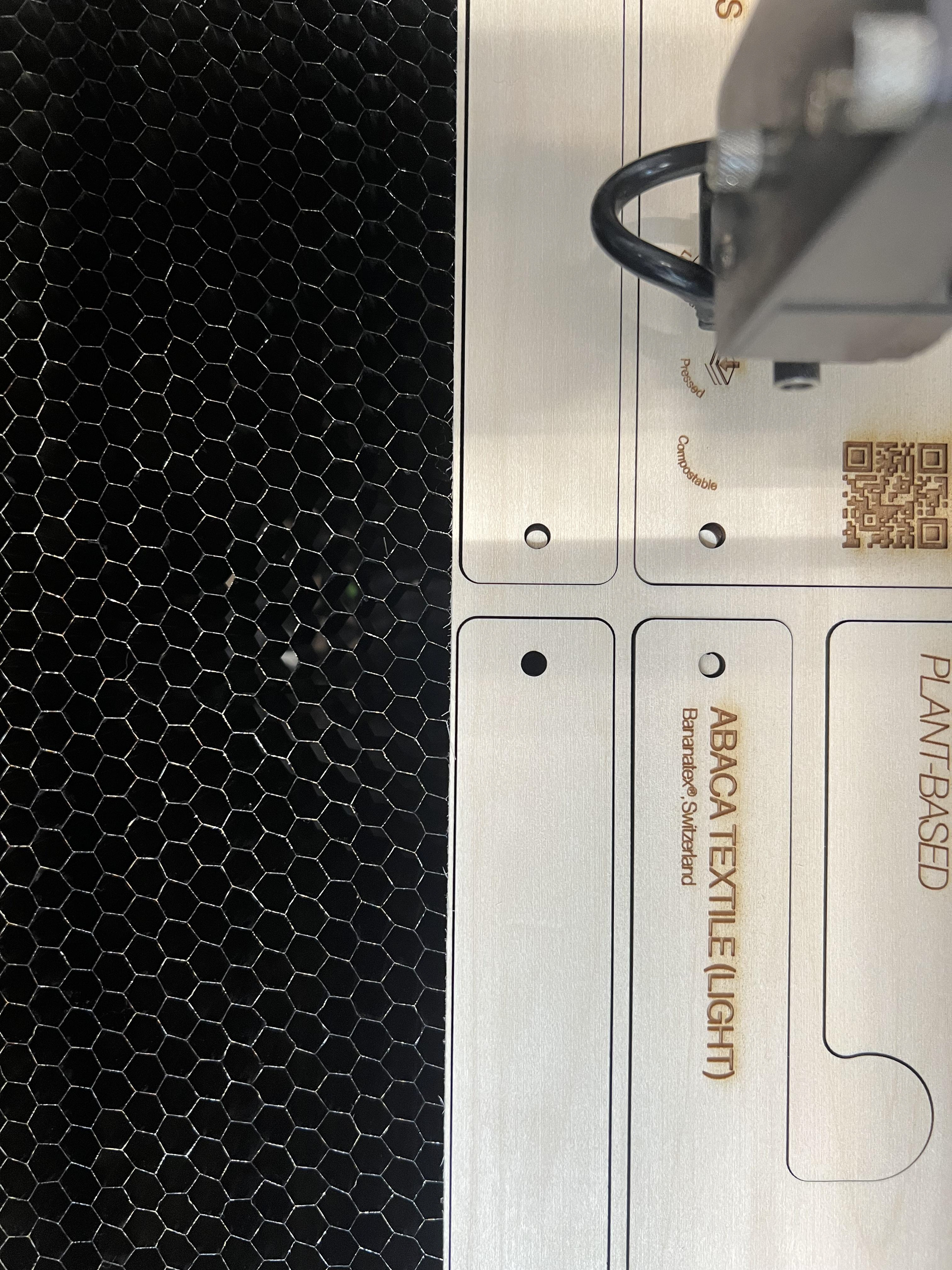

Laser cutting labels onto wood

First round of prototypes

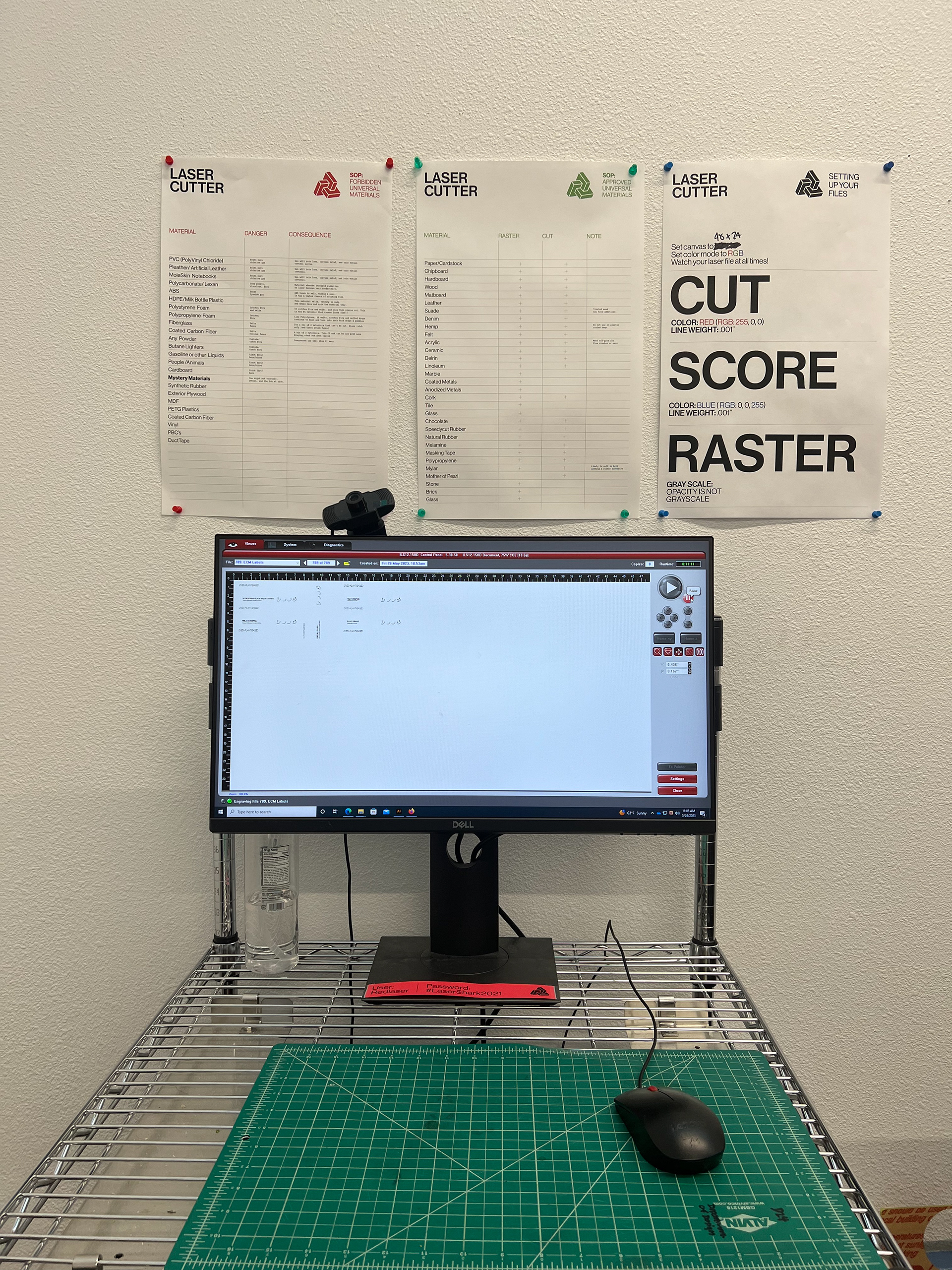

PROTOTYPING PROCESS: Digital Fabrication

In order to cut down on waste, automate the prototyping process, and create a seamless and professional look for the library, I utilized digital fabrication technology, specifically Universal laser cutting machines, when creating signage. By using laser cutting, I was able to create a template for designing my sample labels that can be easily edited when new samples are added to the library.

SOURCING MATERIAL SAMPLES:

In order to create a diverse and comprehensive material library, I needed to supplement the samples that we already had with a wider range of samples that could be made in the lab or that companies are producing on the market.

NETWORKING WITH STARTUPS & COMPANIES:

During my research phase, I researched and kept a list of companies that create sustainable materials and/or are making strides in the field. I kept a spreadsheet of the companies, the type of material they create, and what category the materials fall into (plant-based, animal-based, recycled, fungal, bacterial, natural dyes), then sent an email to representatives explaining the project and inquiring about obtaining samples. The response was overwhelmingly positive, with most companies offering to send samples for free. This was largely how I populated the library with samples from real manufacturers who are already creating products on the market.

CREATING SAMPLES IN THE LAB:

Throughout my time at UC Davis, I was involved in the Sprocket Lab, a lab occupied by the Department of Design aimed at supporting the biodesign and sustainable design emphases. During my time interning in this lab during my junior year, I flexed my experimenting muscle and worked to create 3 bioplastic samples using different recipes. Because of the emphasis on research and prototyping at UC Davis Design, I wanted to include student-made samples in the library, and accomplished this by making several of my own samples to add to the library.

COLLABORATING WITH ALEJANDRA RUIZ, MFA:

A large portion of the samples in the library were created by Alejandra Ruiz as a part of her MFA graduate studies in the Department of Design. Alejandra focused her research on exploring the use of recycled denim fibers in combination with bio-based binders in order to create composite materials that could both be used for the creation of new products, but also that were less harsh on the environment. Alejandra and I worked together in Sprocket Lab over the course of the year to support each others' work and provide help when needed.